1.RWT Microwave high-temperature pusher kiln summary

RWT Microwave high temperature Push plate kiln based on microwave heating The mechanism is different from the conventional heating method. It is caused by the internal friction of materials and the direct coupling of phonons caused by the movement of polarized particles and forced vibration. The material body directly acts as the heating body. This series of equipment has fast heating speed, high production efficiency, uniform heating of products, good product quality, and high energy utilization rate, saving more than 40% energy compared with conventional electric kilns and gas kilns.

2. Structure composition of RWT microwave high-temperature pusher kiln

It is mainly composed of feed airtight bin, microwave suppressor, preheating and heating zone, heat preservation zone, slow cooling zone, quench zone, discharge airtight bin, microwave real-time alarm, propulsion system, protective atmosphere (including weak reducing atmosphere) operating system, heat preservation system, cooling water system, microwave feed system, temperature control system, electric control system, external circulation plate return line and kiln furniture.

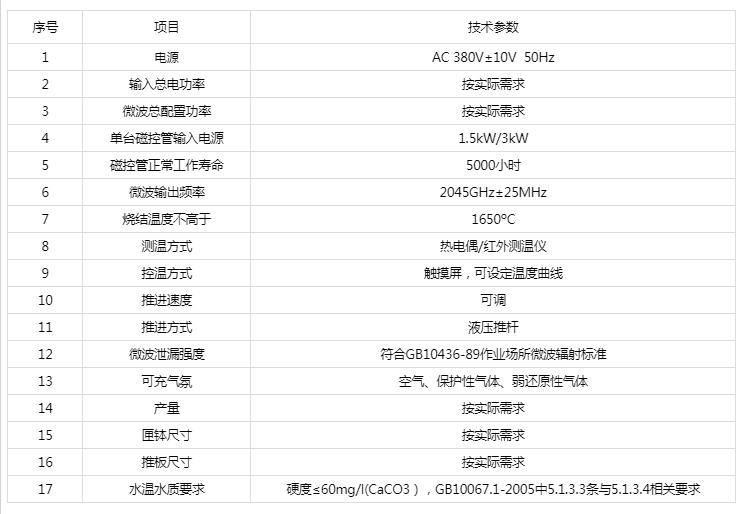

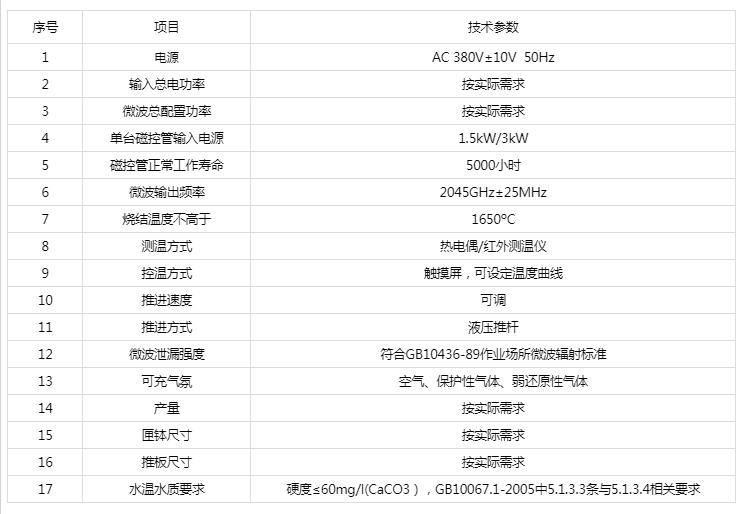

3. Main technical parameters of RWT microwave high-temperature pusher kiln

4. Market application field of RWT microwave high-temperature pusher kiln

Sintering of ferroalloy

Typical materials: vanadium nitride, silicon nitride, manganese nitride, ferromanganese nitride, ferrochromium nitride, etc

Burning of magnetic materials

Typical materials: nickel zinc ferrite, manganese zinc ferrite, neodymium iron boron, etc

Burning of power battery materials

Typical materials: lithium cobalate, lithium manganate, lithium ferrous phosphate, etc

Sintering of electronic ceramic powder

Typical materials: BaTiO3, SrTiO3 powder

Sintering of functional ceramic powders

Typical materials: tricolor phosphor, LED phosphor, etc

Other materials:

Carbothermal reduction of synthetic diamond graphite+coal contact, and carbothermal reduction of metal oxide ore; Oxidative Roasting of Petrochemical Molecular Sieves

5. Typical cases of RWT microwave high-temperature pusher kiln

Brief Process of Microwave Sintering of Vanadium Nitride

Atmosphere: flowing nitrogen;

Pressure: slightly more than one atmosphere;

Heat up and discharge glue → heat up for 2-4 hours to 1250 ℃ → heat up for 1 hour at 1250~1500 ℃ → heat preservation at 1500 ℃: 1 hour → fast cooling.

Brief process of microwave sintering of molecular sieve

Atmosphere: air;

Pressure: slightly more than one atmosphere;

Heat up and discharge glue → 550 ℃ (heat preservation for 180min) → reduce to normal temperature

Carbothermal reduction microwave sintering process of synthetic diamond graphite+coal contact

Atmosphere: nitrogen+2% hydrogen;

Pressure: slightly more than one atmosphere;

Fast temperature rise to 1100 ℃ → 1100 ℃ (heat preservation for 60min) → drop to normal temperature

A Brief Process of Microwave Sintering of Manganese Silicon Nitride

Atmosphere: flowing nitrogen;

Pressure: slightly more than one atmosphere; Heat up and discharge glue → heat preservation for 2h at 700~800 ℃ → fast temperature rise → heat preservation for 4h at 1150~1340 ℃ → heat preservation for 1h at 1450 ℃ → cool down for more than 200 ℃ and take out the furnace.

Can be customized according to customer requirements