1、 Microwave puffing equipment for tobacco stem summary

Microwave puffing equipment for tobacco stems is a continuous puffing equipment for tobacco stems. After being irradiated by microwave, the tobacco stem rapidly heats up and expands 2-3 times in volume. The application of microwave puffed tobacco stem particles in cigarette formulation can not only improve the combustion performance of cigarettes, reduce the woody smell, effectively improve the quality of cigarettes, but also effectively reduce the tar in cigarette smoke, and improve the safety of cigarettes.

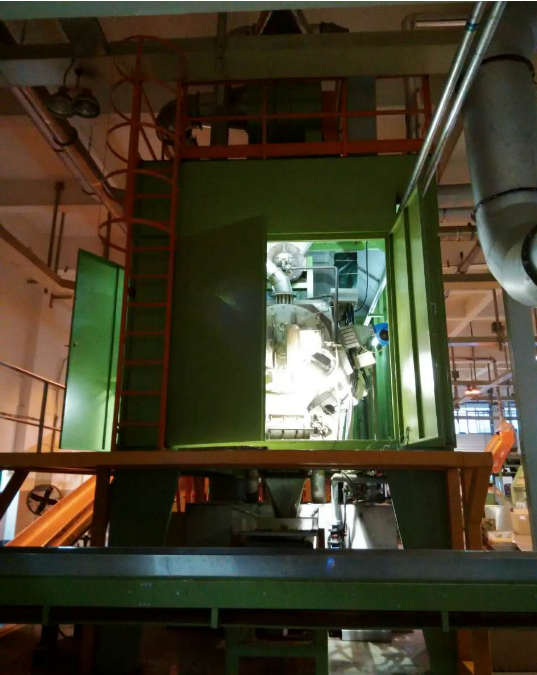

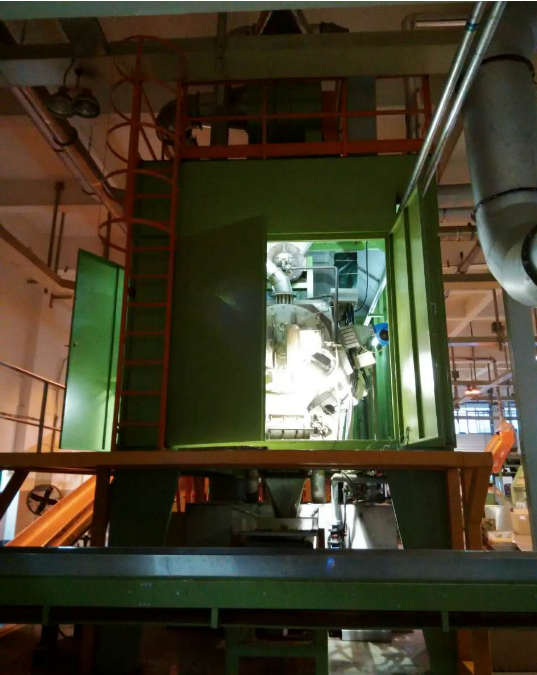

2. Structure of microwave puffing equipment for tobacco stem

The microwave puffing equipment for tobacco stems consists of microwave cavity, furnace tube, mixing shaft, rack platform, microwave energy feeding system, infrared thermometer, cooling water system, automatic fire extinguishing device, control system, etc.

3. Technical parameters of microwave puffing equipment for tobacco stem

1. Power supply: 380V ± 10V/50Hz;

2. Microwave output frequency: 2.45GHz ± 25MHz;

3. Installed microwave power: configured according to actual demand

4. The operating temperature is not higher than 200 ℃;

5. Temperature uniformity: ± 3 ℃;

6. Rotating speed of mixing shaft: variable frequency;

7. Temperature control: automatic control/manual control;

8. Temperature measurement method: infrared thermometer:

9. Microwave leakage intensity:<2mW/cm2, the leakage is far lower than the national standard (GB10436-89)

4. Performance characteristics of microwave tobacco stem expansion equipment:

1. Energy saving: energy saving compared with traditional heating furnace;

2. High quality: microwave overall heating, the product is evenly heated, and the quality is good;

3. High efficiency: high heating speed;

4. Flexible process: heating process curve can be selected and controlled automatically according to different materials;

5. Safe and reliable: equipped with industrial water-cooled microwave source system, which can be used 24 hours without interruption Magnetron It can be replaced online, with its own microwave anti leakage alarm device and safety lock. When the microwave exceeds the standard, it will automatically or manually cut off the microwave power supply;

6. Environmental protection: no waste gas and waste water are discharged from the microwave kiln;

7. Automation: PLC+touch screen control mode, with automatic sintering, automatic data recording, access functions, multiple process temperature curves can be set, with automatic and manual dual operation control functions.

Can be customized according to customer requirements