1、 Product Introduction

RWS-3 Microwave multi-function experimental oven It is a standardized and multi-functional Microwave high temperature The experimental equipment is mainly used for high-temperature sintering, research and development, low-temperature treatment and small batch production of various materials in colleges and universities, scientific research institutes, enterprises and institutions, technology research and development centers and other units. It can be used with protective gas, weak reducing gas, air, oxygen enriched air and under positive pressure. It is characterized by fast sintering speed, high efficiency and wide application range.

2、 Structure composition:

By Microwave Oven Chamber, microwave energy feeding system, vacuum system, atmosphere system, heat preservation system, control system, crucible, infrared thermometer, mobile trolley, circulating cooling water machine, etc.

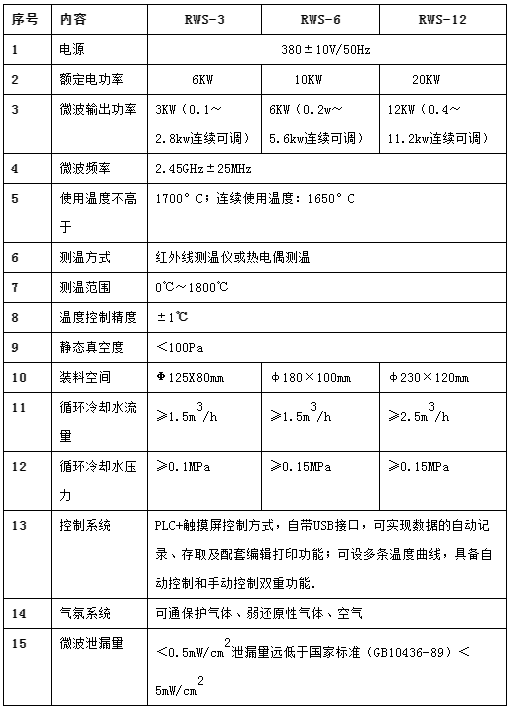

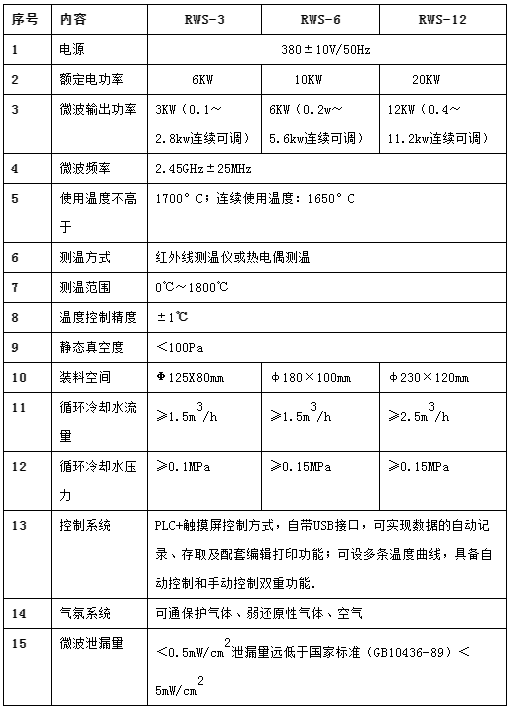

3、 Technical parameters and configuration

4、 Performance characteristics

1. High efficiency: fast temperature rise, 5~20 times faster than the traditional electric heating experimental furnace, which can improve the experimental efficiency;

2. Good product quality: due to the overall heating mechanism of microwave, the product is evenly heated, so the product quality is good;

3. Energy saving: more than 50% energy saving compared with traditional electric heating experimental furnace;

4. Complete functions: It can meet the requirements of atmosphere sintering under various conditions such as protective gas, weak reducing gas, air and oxygen rich gas. The atmosphere entering the furnace cavity is divided into two ways, one is directly into the saggar, and the other is between the furnace cavity and the insulation material, which overcomes the disadvantage that the protective atmosphere of similar products is full of insulation materials, but cannot enter the saggar;

5. Wide temperature detection range: the detection temperature range is usually 250 ℃~1800 ℃, which overcomes the defect that similar products cannot be detected and controlled when the temperature is lower than 400 ℃;

6. The cooling water system is simple: the equipment is equipped with a standard circulating cooling water machine, so the customer does not need to equip a cooling water system, and the installation and commissioning are simple and easy to use;

7. Good matching of microwave energy feeding: double micro wave source feeding mode is adopted, the furnace cavity is rectangular, electromagnetic wave forms diffuse reflection in the furnace cavity, the microwave field in the furnace cavity is uniform, and there is no hot spot due to uneven microwave field during material sintering;

8. Strong operability and easy to use: PLC+touch screen control mode. The touch screen is equipped with its own USB interface, which can plug the USB flash disk into the touch screen. The data of equipment operation is automatically stored in the USB flash disk. The USB flash disk data can be directly edited and printed through the PC; RS232 or RS485 interface is reserved for PLC. (It can be operated by PC) The upper computer can communicate with PLC through the reserved interface to realize the functions of equipment control and data transmission; Multiple temperature control curves can be set, with dual functions of automatic control and manual control; The customer can select the list according to the specific conditions of the experiment Magnetron Or dual magnetron working mode, to avoid damage to magnetron due to low power or high power of magnetron for a long time;

9. Safe and reliable: equipped with industrial water-cooled microwave source system, which can be used 24 hours without interruption. Special microwave shielding sealing ring is used to shield microwave leakage between the oven body and the oven cover; The microwave leakage value of the equipment system is far lower than the national standard (only equivalent to the radiation level when using mobile phones). It has its own microwave leakage prevention alarm device and safety lock. When the microwave exceeds the standard, the microwave source can be cut off automatically or manually.

5、 Scope of application

1. Synthesis experiment of various powders and products:

① Carbides: SiC, WC, TiNC, CrC, VC, etc;

② Nitride: Si3N4, MnxNy, AlN, VN, CrN, etc.

2. Electronic ceramic powder: barium titanate, barium strontium titanate, strontium titanate, barium zirconate titanate, etc.

3. Power battery materials: lithium ferrous phosphate, lithium cobalate, lithium manganate, etc.

4. Molecular sieve for petrochemical industry.

5. Ceramic pigments and glazes of various colors.

6. Sintering experiments of various parts:

① Magnetic materials: nickel zinc ferrite, manganese zinc ferrite, etc;

② Electronic ceramics: BaTiO3, SrTiO3, ZnO piezoelectric ceramics, PTC electric sensors, etc;

③ Special ceramics: MgO structural ceramics, Al2O3, ZrO2, Y2O3, ZnO, MgO, SiO2 advanced structural ceramics;

④ Traditional porcelain: various household porcelain, art porcelain, architectural porcelain, etc;

⑤ Refractory materials, various glasses, inorganic non-metallic materials, ceramics, etc.

Can be customized according to customer requirements