At present, it is developed by the company Industrial microwave equipment Phase I functions of the Internet of Things platform were officially launched Zhongsheng Thermal Energy The realization of industrial interconnection of equipment has laid a solid foundation. Based on the Internet of Things, 3D visualization and intelligent technology, this platform provides equipment basic information management, daily operation and maintenance management, data collection, operation status monitoring (including equipment related indicator monitoring, internal material accumulation monitoring (tunnel kiln, etc.), remote support (including remote data collection, diagnosis and control, etc.) Safety management (including regional intrusion monitoring, flame monitoring, etc.), carbon data management, etc. Through these functions, equipment manufacturers can improve the operation safety and efficiency of equipment, improve the operation and maintenance means of equipment, reduce the operation and maintenance costs of equipment, and ensure the quality of equipment production products.

The platform mainly applies advanced IT technologies such as sensing and IoT technology, image recognition, cloud computing, etc., to provide escort for the normal operation of equipment; At the same time, through the collection and calculation of equipment operation environment, energy consumption and production data, the carbon emission report is automatically generated for the equipment enterprise users Carbon neutralization Strategy and carbon asset management provide basic management means and data sources; The platform also adheres to the open concept, provides rich data and control interfaces, and provides solid technical support for equipment access to larger production lines or systems.

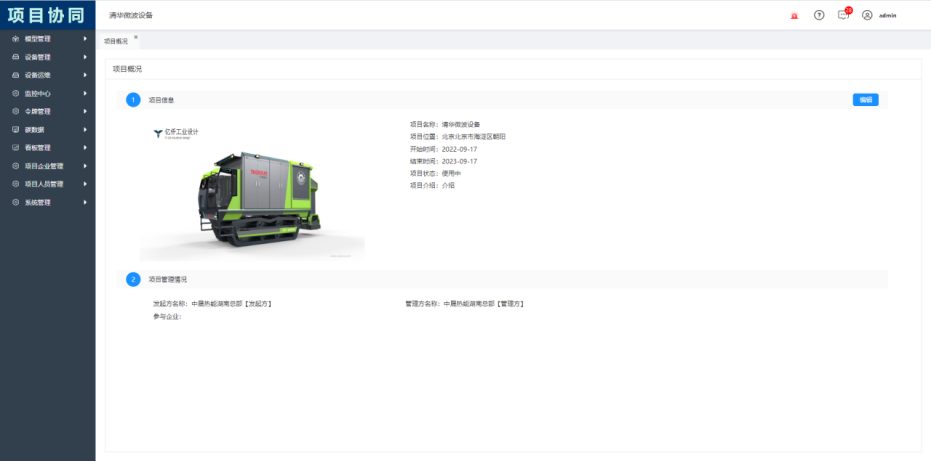

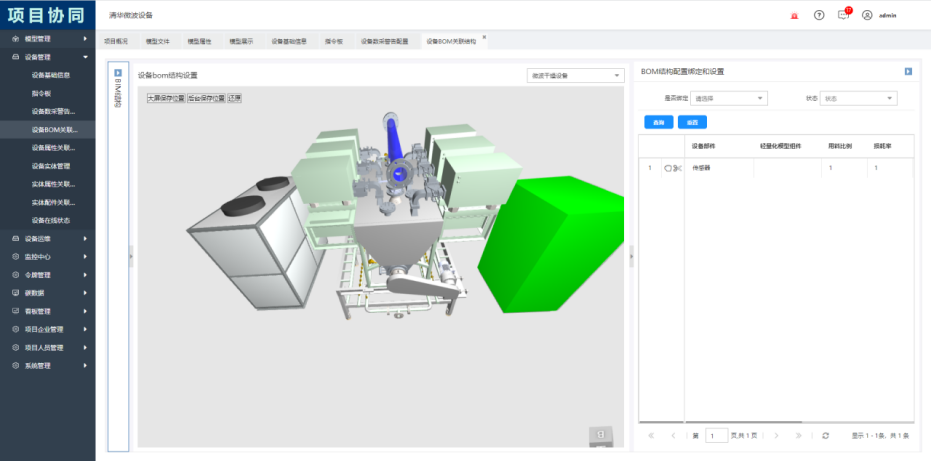

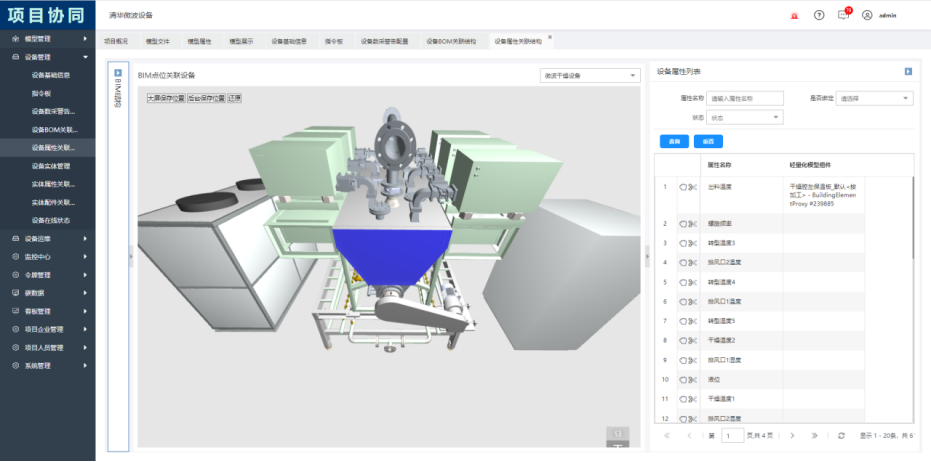

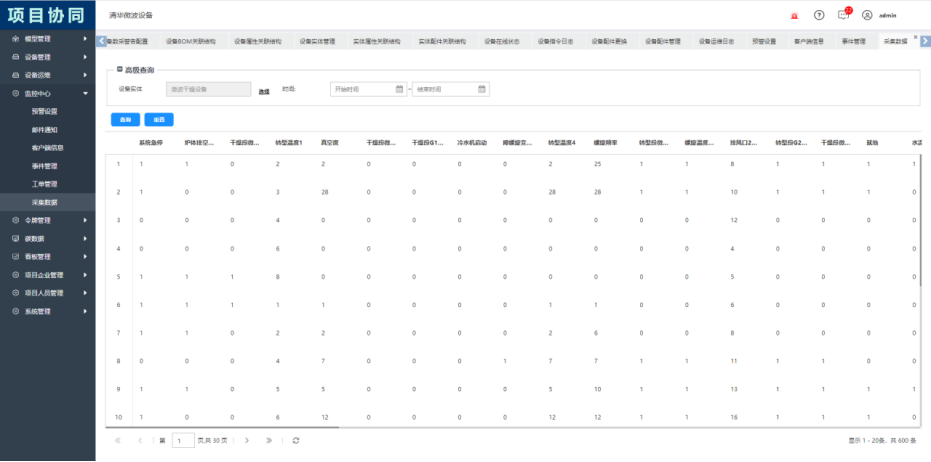

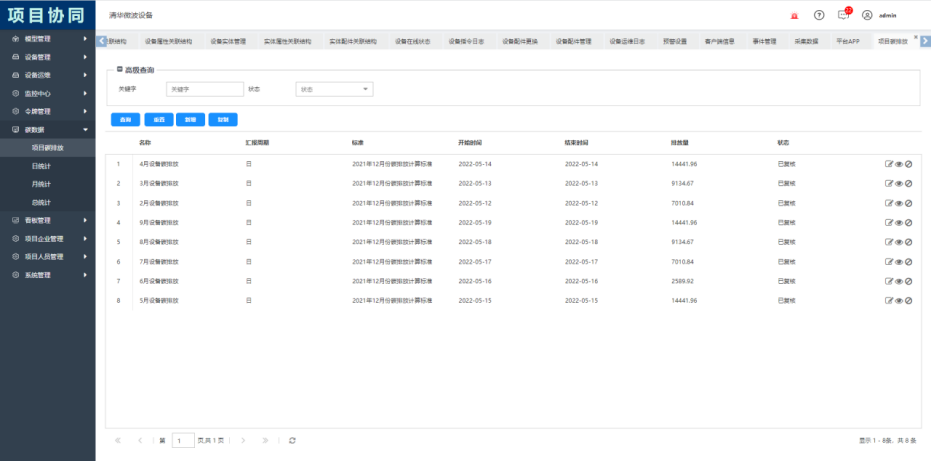

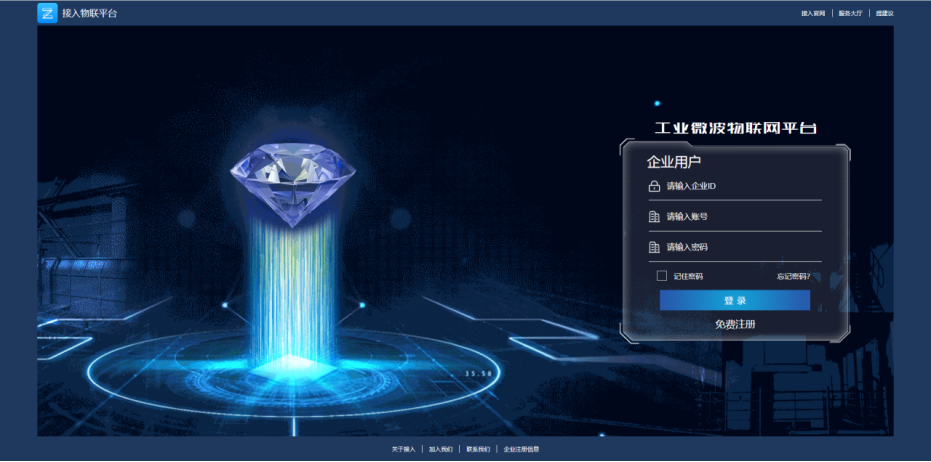

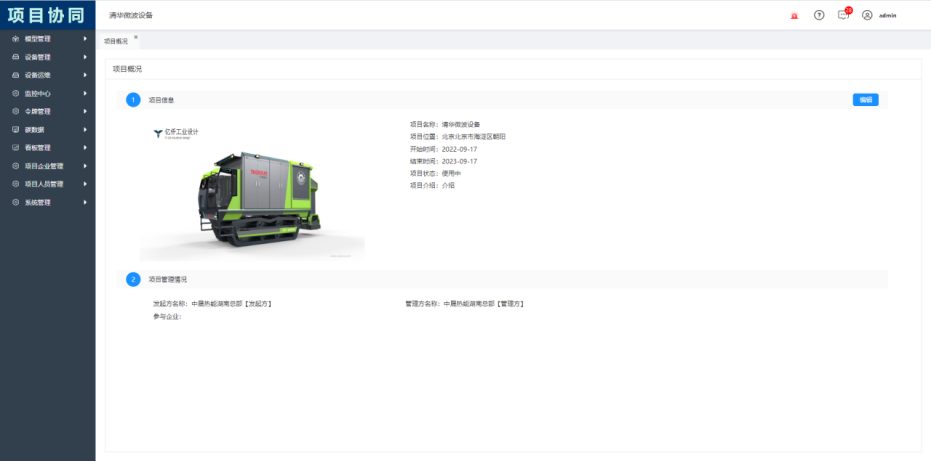

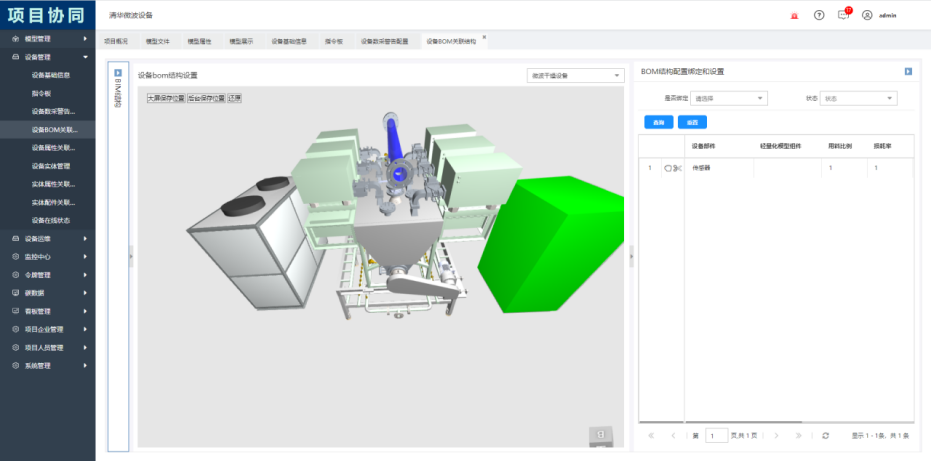

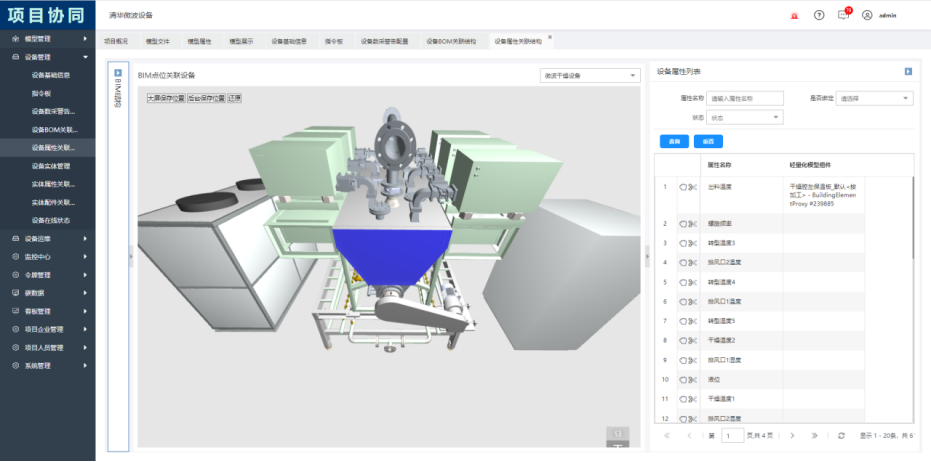

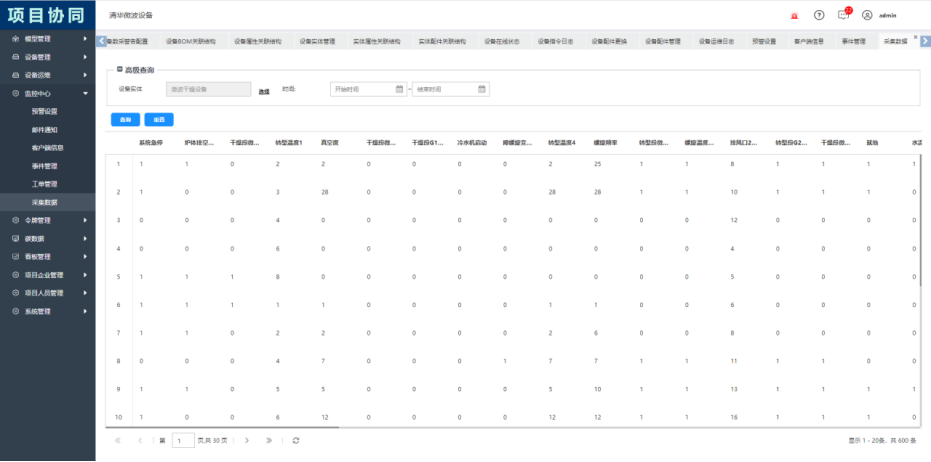

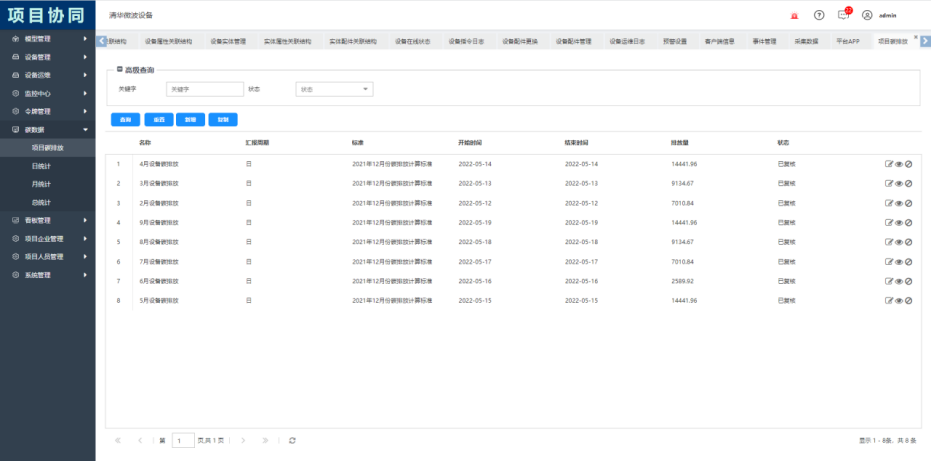

Below are some screenshots of system functions:

1) System login and project

2) Equipment component association

3) Device Attribute Association

4) Equipment data acquisition

5) Equipment carbon emission

6) 3D visualization