1、 Overview

The equipment is mainly used for baking large quantities of non-metallic materials in air atmosphere. This equipment has high energy utilization rate, short firing cycle, high production efficiency, large daily output, uniform product heating, good product quality, flexible process adjustment, strong operability, high degree of automation, convenient use, safety and reliability, small floor area, and no environmental pollution. This series of equipment is suitable for sintering and synthesis of non-metallic materials under air atmosphere and oxygen rich conditions Disassembly and glue removal, etc.

2、 Structure composition

From the feed section, feed microwave suppressor microwave heating The heating zone, microwave heating insulation zone, slow cooling zone, fast cooling zone, discharge microwave suppressor, discharge section moisture removal system, transmission system, steel belt, correction system, automatic steel belt tensioning system, microwave feeding system, temperature control system, electrical control system, etc.

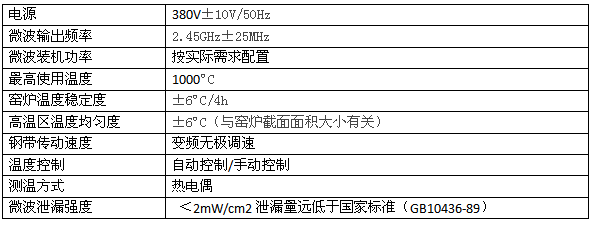

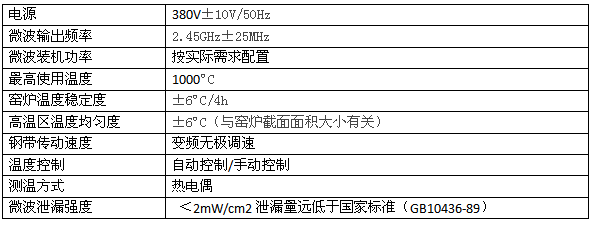

3、 Technical parameters

4、 Performance characteristics

1. Energy saving: more than 40% energy saving compared with traditional heating furnace;

2. High quality: microwave overall heating, the product is evenly heated, and the quality is good;

3. High efficiency: the heating speed is fast, 5-15 times that of the traditional electric heating kiln;

4. Flexible process: heating process curve can be selected and automatically controlled according to different materials;

5. Safe and reliable: it is equipped with an industrial water-cooled microwave source system, which can be used 24 hours without interruption. The microwave magnetic control can be replaced online. It has its own microwave leakage prevention alarm device and safety lock. When the microwave exceeds the standard, it can automatically or manually cut off the microwave source;

6. Small floor area: 1/2 of that of ordinary electric kiln;

7. Environmental protection: no waste gas and waste water are discharged from the microwave kiln;

8. Automation: PLC+touch screen control mode, with automatic control, automatic data recording, access functions, multiple process temperature curves can be set, with automatic and manual dual operation control functions.

5、 Scope of use

Calcination of mica flakes, treatment of waste salt, thermal decomposition and oxidation of minerals, impurity removal of metal oxides, etc.

The above parameters are for reference only, and technical parameters can be formulated according to customer requirements.